In the modern manufacturing world, stainless steel is everywhere—from kitchen appliances to architectural facades, automotive components, and medical instruments. But not all stainless steel is created equal; some stainless steel materials are capable of bending, while some are not. It is not because the quality is bad, it is only that the processes the material went through are different and it changes the properties. Among the most commonly used forms, cold-rolled stainless steel (CRSS) has emerged as a versatile material that offers both precision and performance for demanding industrial applications.

In this article, we will explore what cold-rolled stainless steel is, how it is produced, why it is important, and how industries like construction, automotive, and electronics rely on it.

A Brief Introduction to Cold-Rolled Stainless Steel

Cold-rolled stainless steel is produced by rolling stainless steel at room temperature, below its recrystallization temperature. Unlike hot-rolled stainless steel, which is rolled at high temperatures and typically has a rougher surface, cold-rolled stainless steel undergoes controlled deformation to create a smooth, uniform surface with precise thickness tolerances.

This process not only improves the surface finish but also enhances mechanical properties such as hardness, strength, and dimensional stability. It is ideal for applications where precision and aesthetics are both critical.

How Cold-Rolled Stainless Steel is Made

The production of cold-rolled stainless steel involves several key steps:

1.Pickling and Cleaning

Stainless steel coils are first cleaned to remove any surface impurities and oxides formed during previous processing stages. This step ensures that the metal is ready for rolling without surface defects.

2.Cold Rolling

The stainless steel is then passed through a series of rollers that progressively reduce its thickness. Rolling at room temperature improves dimensional accuracy and produces a smooth, shiny surface that is often suitable for direct use in fabrication or finishing processes.

3.Annealing

After cold rolling, the steel may be annealed to relieve internal stresses and improve ductility. Annealing helps the metal retain its workability, making it easier to form, bend, or cut in downstream manufacturing.

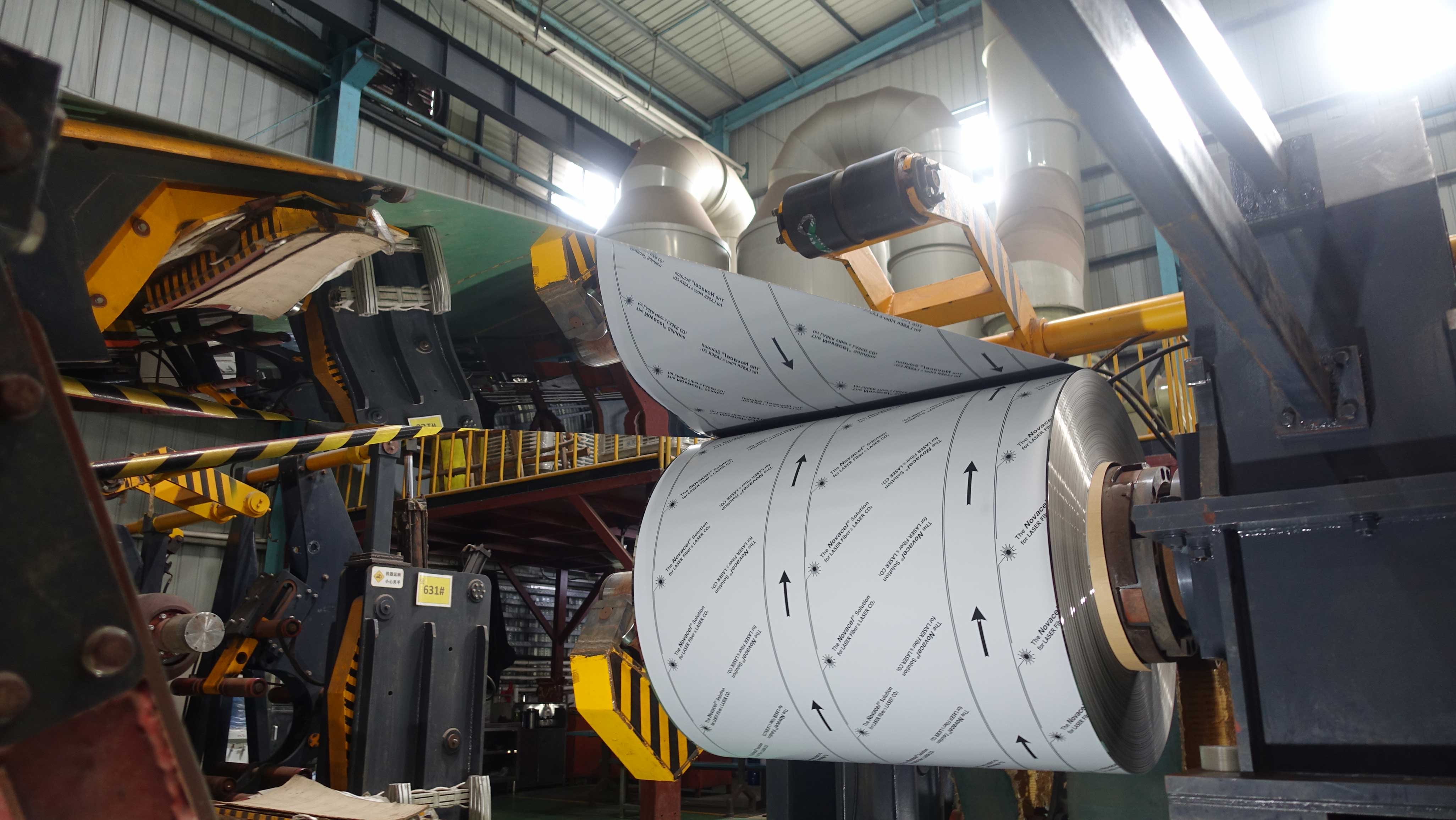

4.Finishing and Coiling

Finally, the cold-rolled stainless steel is polished, leveled, and recoiled into standard sizes. Edge trimming or conditioning may also be applied to ensure safe handling and uniformity.

Key Characteristics of Cold-Rolled Stainless Steel

Cold-rolled stainless steel is known for a combination of mechanical and aesthetic properties:

•Smooth Surface Finish: Ideal for decorative applications or visible surfaces.

•Dimensional Precision: Tight thickness tolerances are critical for precision fabrication.

•Improved Strength: Cold working increases yield and tensile strength compared to hot-rolled steel.

•Enhanced Formability: Properly annealed CRSS can be formed into complex shapes without cracking.

•Corrosion Resistance: Retains stainless steel’s inherent corrosion protection, enhanced further by surface finishing.

These characteristics make cold-rolled stainless steel suitable for a wide range of industries, from household appliances to industrial machinery and automotive parts.

Applications of Cold-Rolled Stainless Steel

Cold-rolled stainless steel is widely used in applications that demand precision, durability, and visual appeal:

•Automotive Industry: Panels, trim, exhaust components, and structural elements.

•Construction and Architecture: Elevator panels, railings, decorative cladding, and roofing.

•Food and Beverage Equipment: Stainless countertops, sinks, and food processing equipment.

•Medical Devices: Surgical instruments, trays, and other equipment requiring smooth surfaces and corrosion resistance.

•Electronics and Electrical Applications: Casings, enclosures, and precision components.

By providing both structural integrity and a visually appealing finish, cold-rolled stainless steel enables manufacturers to meet the strict requirements of modern industries.

Choosing the Right Grade for Cold Rolling

Not all stainless steel grades are equally suitable for cold rolling. The most common choices include:

•Austenitic Stainless Steel (300 Series): Highly corrosion-resistant and excellent for deep drawing.

•Martensitic Stainless Steel (400 Series): Stronger and harder, often used for cutting tools and blades.

•Ferritic Stainless Steel: Offers moderate corrosion resistance with good formability.

The choice of grade depends on the mechanical requirements, corrosion resistance needs, and forming processes of your application. At JINLING METALS, we provide a range of grades suitable for cold rolling, ensuring optimal performance in every application.

Why Cold-Rolled Stainless Steel Matters

Using cold-rolled stainless steel brings multiple advantages:

1.Precision Manufacturing: Ensures uniform thickness, enabling better fit and function in assembly.

2.Enhanced Surface Quality: Reduces the need for post-processing, saving time and costs.

3.Durability: Cold rolling improves hardness, extending the life of components.

4.Aesthetic Appeal: Smooth, reflective surfaces meet both industrial and consumer demands.

5.Cost Efficiency: Minimizes material waste and improves yield in fabrication.

With these benefits, cold-rolled stainless steel has become a preferred choice for industries where quality, performance, and appearance are equally important.

Partnering with JINLING METALS for Cold-Rolled Stainless Steel

At JINLING METALS, we specialize in high-quality stainless steel products, including cold-rolled coils and strips tailored to your specifications. We combine advanced manufacturing techniques, stringent quality control, and global supply capabilities to ensure that every coil meets your exact requirements.

Whether you are producing automotive components, architectural elements, or precision instruments, our technical expertise and wide alloy selection help you achieve optimal performance while maintaining cost-efficiency.

Contact our experts today to learn more about our cold-rolled stainless steel products and request a quote for your next project.

Conclusion

Cold-rolled stainless steel is a versatile, high-performance material that balances strength, precision, and aesthetics. Its unique production process ensures consistent thickness, smooth surfaces, and improved mechanical properties—making it essential for industries ranging from automotive to medical, electronics, and construction.

Choosing the right grade and supplier can dramatically impact the efficiency, safety, and quality of your products. By partnering with JINLING METALS, you gain access to expertise, high-quality materials, and tailored solutions that meet the demands of modern manufacturing.