All about JINLING’s soul.

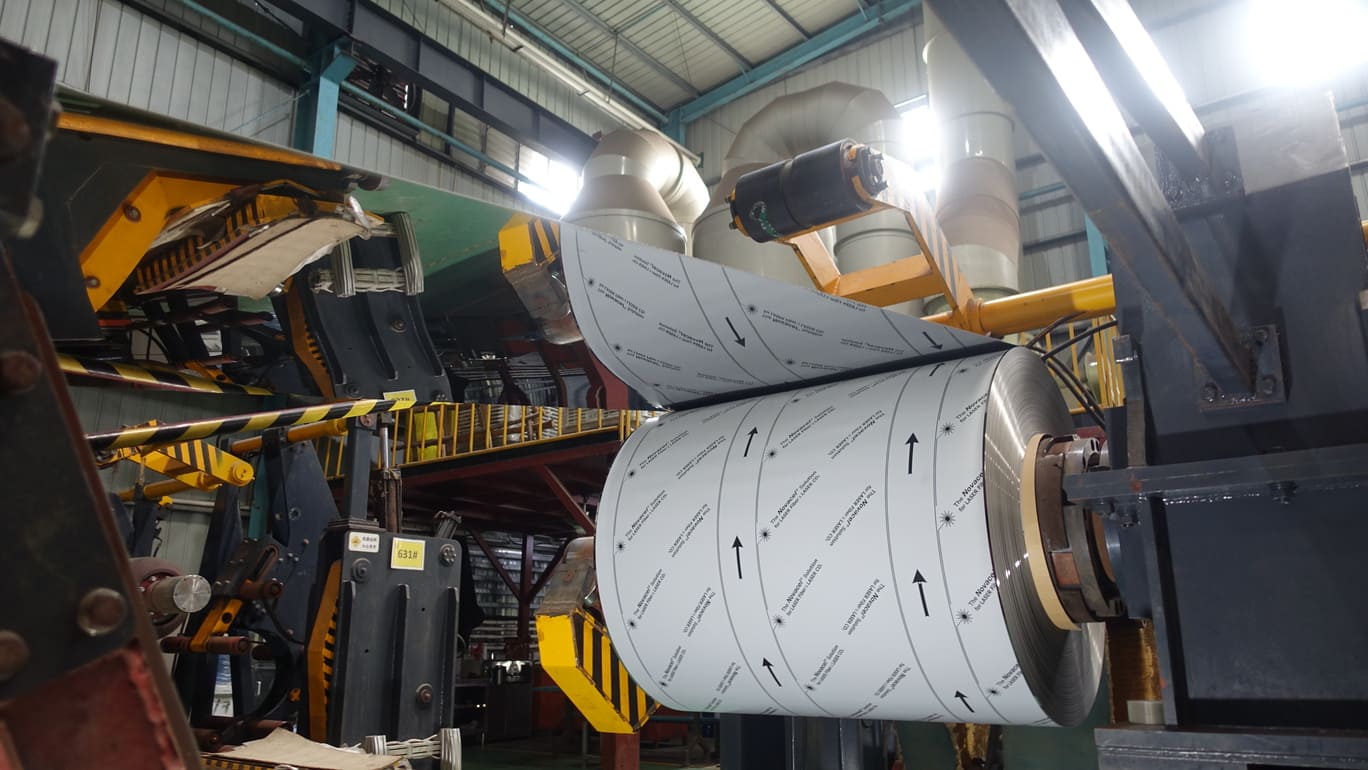

Founded in 1997, we started our professional journey in stainless steel industry and providing services and materials to clients around the world. For over 20 years, we are dedicating to produce flat and long stainless steel products with a wide range of standards like martensite, austenite which can be classified into 200 series, 300 series and 400 series in customized specifications and surfaces. During the years, we have developed our own service philosophy, the just-right products are the best to our clients. Customers from various industries such as home appliances, kitchenware, building material for exterior and interior, mechanical engineering and wholesalers as well, have come to us with different demands for stainless steel. Rooted from clients’ specific requirements, Jinling Metals is capable in adjusting our products that tailored to meet the on-of-kind needs.

What we value most, is people, not only people who buy from us but also people who work with us. We understand that the success of a project, of a company, is generated by people. We build a relationship that is of mutual respect, trust, equal, and free with our employees. It is our essence in our company culture that we make our workplace with an environment happy, united, effective, and fulfilling.

It is one of the major reasons why we keep pursuing in stainless steel industry. Stainless steel is a 100% sustainable metal material without any degradation during reusing. When promoting and producing this excellent material, we believe that we are helping to build a better and more sustainable world.

As we confront more and more circumstances that require us to keep updating with the new challenges coming with new designs and trend. Our team has a strong force and faith to make new attempts with our customers and improving our processing skills.

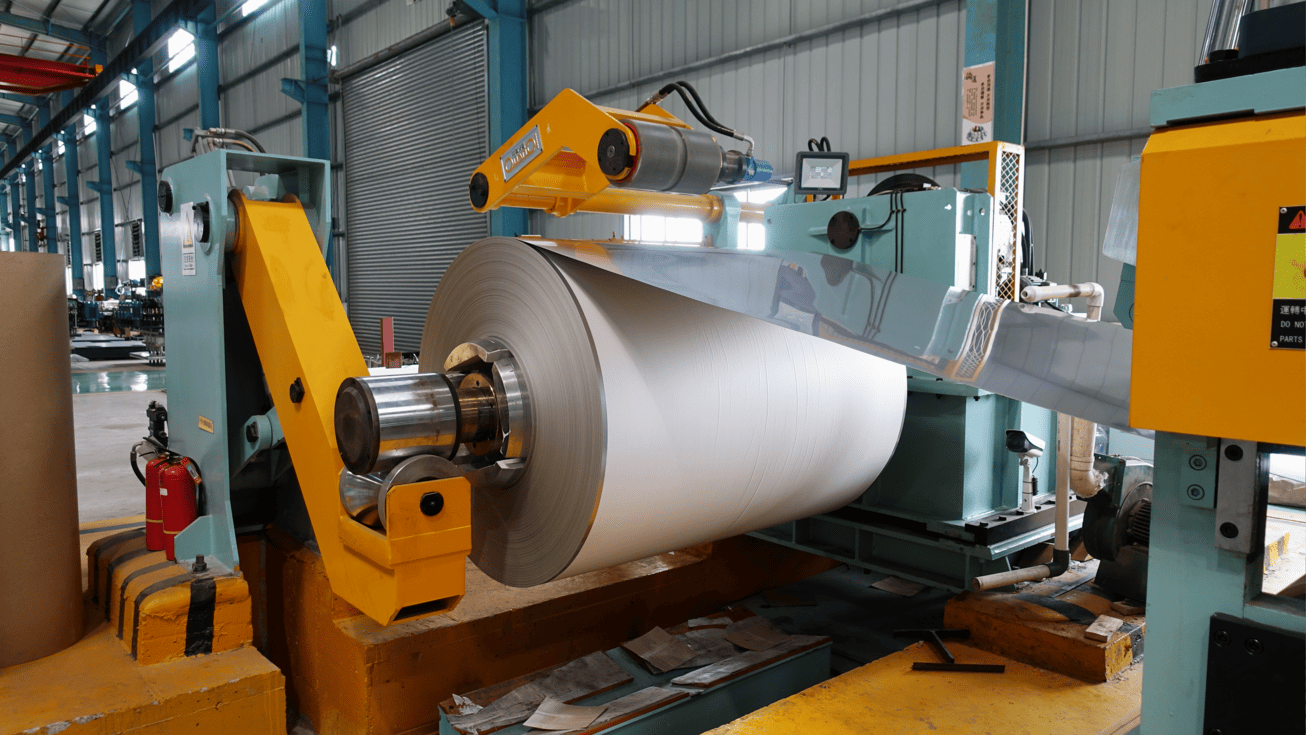

Located in Foshan China, a major stainless steel center, Jinling Metals is capable to shiftly respond to market dynamics, helping our customers to grasp Chinese market easily. Our manufacturing station is equipped with machines to slit, cut, and surface processing such as mirrored, embossed, anti-fingerprint and common surface effect like No.1, 2D, 2B, No.4, hairline, BA and etc.